Line Sizing Calculation (Part 1)

1.1. Flow Rate, Temperature and Pressure

Flow rate, pressure, and temperature for all process lines

used for line sizing calculation will be taken from the material balance from

Process Flow Diagram.

1.2. Line Sizing Criteria

The criteria shown on

Table 1 will be used to determine the line size. Such criteria are based on the

engineering practice used to select the economic size of piping inside the

plant battery limit.

Items

|

|

1. Gas/Vapor Lines

|

Pressure Drop(3)

- DP per 100 m < 0.117 bar (P < 34.3 barg)

- DP per 100 m 0.117-0.274 bar (34.3 < P < 137.2 barg)

Velocity(1)

-Velocity

< 18.3 m/s

|

2. Liquid Lines

|

For

Continuous & Non Continuous Lines:

- DP

per 100 m < 0.9 bar (2)

-

Velocity: <4 .6="" m="" s="" sup="">(1)

|

3. Two Phase Line

Velocity(4)

-

Velocity 4.6-15.2 m/s

-

Velocity must below than Verosion

Note:(1) Recommended

Practice for Design and Installation of Offshore Production Platform Piping

System, API RP 14E.

(2) Flow of Fluids through Valves,

Fittings, and Pipe

(3) Norsok

Standard No. P-CR-001-Rev 2

(4) Surface

Production Operation Vol. 1

Table 1.

Line Sizing Criteria (Main Process Line)

3.4. Equations

3.4.1.

Liquid phase

Liquid velocity

can be determined from following equation:

where Q : liquid flow

rate, kg/hr

r :

liquid

density, kg/m3

d

: pipe ID, mm

n : mean velocity of flow, m/s

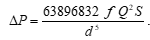

Pressure drop (DP,

kg/cm2/100 m) is determined by fanning equation from API 14E:

Where f : Moody friction factor

Q :

liquid flow rate, m3/hr

S :

liquid specific gravity, dimensionless (water=1)

d : inside

pipe diameter, mm

Reynolds number (Re) of flow in pipe is

calculated from the following equation:

Where d : inside pipe diameter, mm

n : mean velocity of flow, m/s

r : liquid density, kg/m3

m : viscosity, kg/m.s

Friction

factor is calculated based on the following Colebrook's equation (ref: Oil field processing of petroleum vol.1

If Re>2000, use equation :

Where f : Moody friction factor

e :

surface

roughness, mm

D :

internal

diameter, mm

Re : Reynolds number

3.4.2.

Gas phase

Actual gas velocity can be determined by:

where Qg : gas

flow rate, Std.m3/hr

T : temperature,

oK

P : pressure,

kg/cm2a

d : inside pipe diameter, mm

v : gas velocity, m2/sec

Z : gas compressibility factor,

dimensionless

For compressible fluid with total pressure drop less than

10% of its initial pressure, the pressure drop (DP, kg/cm2/100 m) is

calculated using equation from API 14E as follows:

……………….……….(6)

S : gas specific gravity at standard condition,

dimensionless

Qg : gas flow rate, std.m3/hr

Z : compressibility factor, dimensionless

T1

: flowing

temperature, oK

f : Moody friction factor, dimensionless

L : length of pipe, m

P1 : upstream pressure, kg/cm2a

d : inside pipe diameter, mm

3.4.3. Gas/liquid

Two-phase

The fluid erosional velocity (Ve, m/s) is calculated using the following equation (API

14E):

Total weight flow of fluids is the sum of weight flow of

gas and weight flow of liquid. Weight flow of gas can be calculated by equation

below:

……………………....…….(8)

Where:

Gas flow :

mass gas flow (kg/s)

Qg : volumetric volume of gas, Std

m3/hr

Sg :

gas specific gravity

Note: standard gas volume 0.024 m3/gmole is

taken at pressure 1 atm and temperature 15oC

Weight flow of liquid can be calculated by

equation below:

Liquid

flow : mass liquid flow (kg/s)

Ql : volumetric volume of

condensate, m3/hr

Sl : gas

specific gravity

Total

fluid mass flow is the sum of gas flow and liquid flow:

…..…………....(10)

The total volume flow would be:

….……..……...(11)

Where

:

Volume

flow : volumetric flow, m3/s

Total

flow : fluid mass

flow, kg/s

rmixture : gas/liquid mixture density, kg/m3

Mixture velocity could be determined from following

equation:

Where :

V : velocity, m/s

d : inside diameter of pipe, mm

The pressure drop (DP,

kg/cm2/100m) in a two-phase steel piping system is estimated using

simplified Darcy equation (API 14E):

………………………..…(13)

f : Moody friction factor, dimensionless

d : inside pipe diameter, mm

rm : gas/liquid mixture density, kg/m3

W : total liquid plus vapor rate, kg/h

Please go to part 2 for example of calculation .

Komentar

Posting Komentar